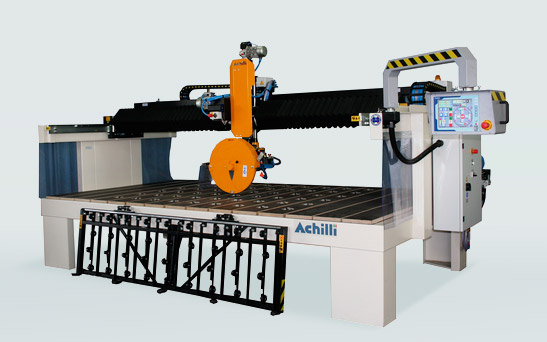

ACHILLI GOLD CNC

Customizable according to customer requirements;

Monoblock structure for easy installation (does not require foundation);

Automatic head rotation;

Precision Stone Cutting: extremely accurate and consistent stone sawing.

Simple to Operate: GOLD is capable of fully automatic operation or can be operated in a semi-automatic mode to give the operator full control of sawing operations;

Manual or CNC controlled head tilt from 90 to 0 degrees;

1/2” gas connection for mounting core drills and perform an automatic drilling cycle to easily cut corners and remove the tension from the sintered material plates;

Pre-loaded parametric figures such as hexagon, octagon, kitchen top, trapezium, polygon, etc.

Profiling environment of the CNC to create artistic frames and decorations.

ACHILLI MBS SAW

ACHILLI MITER SAW FOR 45 DEGREE CUTTING MSA

ADVANTAGES

MSA professional miter saw for tilted cuts:

Steel frame with hot-dip galvanizing treatment for maximum resistance to wear and rust;

Worktable made of anti-scratch plastic material slats;

Available in two models: useful cut 3300mm or 3700mm;

Maximum cutting precision is guaranteed by the head travelling on linear guides fitted with recirculating ball slides automatically lubricated;

10 pneumatic pistons and 3 slab stops to secure even the smallest workpieces in place during machining;

Pneumatic pop-up slab stops to cutthin ceramic and sintered material slabs;

Digital displays to visualize disc rpm, feed speed and main motor ammeter;

Removable plastic splash guards, along the entire worktable;

Precision handwheel to adjust the blade position when the cut does not start on the sharp corner.

ACHILLI TOP TOP MANUAL WORKING CENTER

ADVANTAGES

TOP multipurpose machine for kitchen countertops:

TOP is a multipurpose machine that allows the operator to do different jobs with only one machine with a reduced investment: sink cut-outs, shaping and polishing internal and external contours, drilling and recess drains;

All the job is performed without moving the piece;

Although it is a manual machine, it does the same job as a CNC working centre;

it does not require an experienced operator, anybody with a short training can work on this machine;

Ideal for a small or new factory minimizing investment, reducing production costs and time to manufacture the finished products;

It allows to create complete kitchen and bathroom countertops;

Possibility to use templates to create washbasins